How-To-Guide to Safely Carry Out Electrical Work Involving Asbestos

Like it? Share it!

20 December 2024

The Fire Industry Association (FIA) is committed to supporting safe practices in the fire and electrical industries. In collaboration with leading organisations and experts, we have helped to develop this detailed guide to managing asbestos in electrical work. The guide provides practical advice aligned with UK regulations, equipping professionals to effectively minimise risks, ensure compliance, and maintain the high standards required in fire safety. Through this collaborative effort, we aim to provide valuable resources that prioritise safety and promote industry-wide competency.

Working with asbestos can seem daunting, but with the correct process, tools, and training, you can ensure the job is completed safely, efficiently, and in full compliance with UK regulations.

This guide walks you through everything you need to know—from identifying asbestos to training, installation, and disposal.

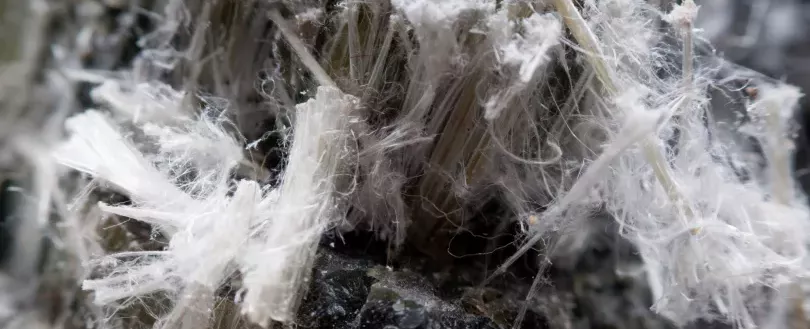

Step 1: Identify If Asbestos Is Present

Before starting any electrical work, it’s essential to confirm whether asbestos is in the area by:

Checking the Asbestos Register or Survey: If you’re working in a building, there should be a register or survey outlining where asbestos is located.

Testing the Material: If in doubt, send samples to an accredited laboratory for analysis.

Skipping this step could expose workers to unnecessary risks or cause costly delays later.

Step 2: Get the Right Training for Non-Licensed Asbestos Work

Training is mandatory for anyone carrying out work where asbestos may be disturbed. The training requirements fall into three levels:

Category B1: Initial Training

- Who it’s for: Individuals with no previous asbestos awareness training.

- Duration: 1½ days (minimum of 9 hours).

Category B2: Intermediate Training

- Who it’s for: Individuals who’ve completed certified asbestos awareness training (e.g. UKATA) within the past 6 months.

- Duration: 1 day (minimum of 6 hours).

Category B3: Refresher Training

- Who it’s for: Individuals who’ve completed any of the above within the last 12 months.

- Duration: ½ day (minimum of 3 hours).

What Training Covers (based on HSE’s HSG210 Asbestos Essentials):

- Required equipment

- Proper use of PPE/RPE (personal protective equipment / respiratory protective equipment)

- Steps to minimise exposure and prevent spread

- Decontamination processes

- Handling asbestos waste

Investing in training will protect your team, reduce risks, and keep you compliant.

Step 3: Verify Subcontractor Training

If subcontractors are involved, don’t assume their training is up to date. Always:

- Request proof of training that meets the standards outlined above.

- Ensure they’re prepared to follow all asbestos protocols.

Skipping this step can result in delays, extra costs, or unsafe practices on site.

Step 4: Installation – Best Practices

Follow the Correct Installation Grade

When installing electrical systems near asbestos, adhere to standards such as:

- BS 5839-1

- BS 5839-6

- BS 7671

Note: You usually don’t need to alter the recommended installation grade, as asbestos processes remain consistent.

Use the Foam Method for Safer Work

The shaving foam method is an effective way to reduce asbestos disturbance during work on battery or mains-powered units:

- Apply shaving foam or wallpaper paste to minimise fibre release during drilling or fixing.

- For full guidance, refer to HSE’s Task Sheet A26.

Install Accessories to British Standards

When fitting accessories such as sockets or conduits, follow British Standards to ensure work is safe, justified, and compliant.

Step 5: Dispose of Asbestos Waste Properly

Disposing of asbestos waste requires careful planning. Here are your options:

Registered Waste Carrier

- Use a licensed waste carrier for collection and transport.

- Check the Environment Agency’s waste carrier register (there are around 365,000 registered carriers in the UK).

Temporary Storage (NWFD3 Exemption)

- You can temporarily store bonded asbestos waste for up to 3 months in a controlled location.

- For details, see NWFD3 Guidance.

Waste Transfer Station

- A hazardous waste consignment note is required. Learn more: Hazardous Waste Guidance.

- Licensed Landfill Sites

- As of 2024, there are only 12 licensed landfill sites in the UK that accept asbestos waste. Plan accordingly.

Step 6: Health and Safety Considerations

Safety is paramount when working with asbestos. Here’s what you need to remember:

Document Everything – Complete a detailed Method Statement and Risk Assessment before starting work.

Follow Regulations – Work at Height Regulations 2005. Construction (Design and Management) Regulations. COSHH Regulations 2002.

Use the Right PPE and RPE – Wear suitable RPE (face mask) with P3 filtration. Ensure workers are clean-shaven to guarantee a proper RPE seal.

Silica Dust Risks – When silica dust is present, wear RPE with P3 filtration to prevent inhalation.

Fit Testing for RPE – RPE must be face-fit tested by a competent professional. For guidance, see: HSE Fit Testing.

Final Thoughts

Working safely with asbestos is all about preparation, training, and compliance. By following this step-by-step guide, you can ensure your electrical work proceeds without unnecessary risks or delays. Stay safe, stay compliant, and always prioritise health and safety on site.

This guide was created in collaboration with the following organisations: Aico, UKATA, ATL Safety, Wolverhampton Homes, Believe Housing, FIA, Places for People, St Leger Homes, Bradley Environmental Consultants Ltd.

View the source.

Related training

Related news

-

Record Rise in E-Bike and E-Scooter Fires Across London

28 January 2026

-

Guidance on IP Connectivity and Remote Services

19 January 2026